Project Path

The Industrial Path Planning Software Tailored for Industries.

Your Production. Our Optimization.

The Future of Additive Manufacturing.

3D printing offers amazing freedom in design and saves materials, but maintaining consistent quality and process stability is still tough. This is especially true for industries where safety and structural strength are non-negotiable – like aerospace, automotive, and medical tech.

Project Path is powerful software that optimizes your 3D printing process (FLM).

- Unlock New Opportunities: Combine design freedom with industrial-grade manufacturing efficiency.

- Reliability Guaranteed: Consistent quality for safety-critical applications.

- Built for the Future: Machine- and material-agnostic with the flexibility to expand to other processes.

Project Path changes the game by combining the speed and efficiency of FLM with unmatched process reliability that meets the highest industry standards. With our platform, you upload your machine code, optimize it, and integrate it back into your workflow effortlessly. The improved path planning delivers consistent material flow, stronger parts, and less waste. Project Path doesn’t just meet industry standards – it exceeds them, unlocking a new level of innovation for additive manufacturing.

Challenges in 3D Printing:

- Unpredictable part quality

- Large tolerances

- Limited software capabilities

Project Path:

- Consistent, predictable part quality

- Tight tolerances for precision

- Improved material properties

Applications

Traditional slicers often can’t handle the complexity needed to make consistent quality and process reliability, resulting in uneven material deposition, costly waste, and production delays. Ensuring consitent part quality allows for more than “just” better parts. It allows for new designs and new applications of 3D printing. Here’s just a little sneak peak what we and our partners were able to achieve with Project Path’s Gcode optimization:

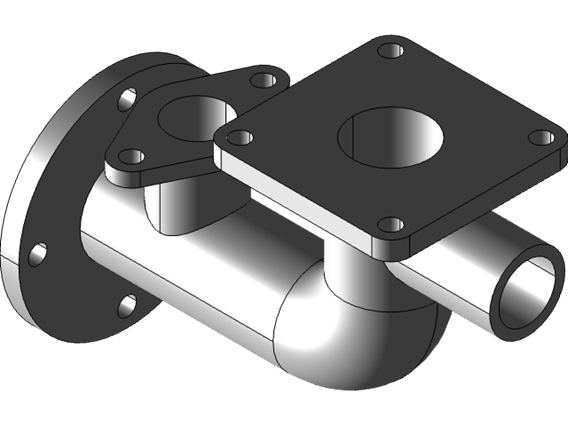

Sinter Materials

Problem: Producing sintered parts with smooth surfaces and flawless finish is challenging. Traditional processes risk defects during post-processing.

Solution: Project Path enables precise and consistent filling of even complex geometries, minimizing defects and improving overall quality.

Result: Applied to a pipe flange for fluid transport, Project Path increased material density and drastically reduced flaws.

Compressed Air Systems

Problem: Post-processing of sintered parts can cause defects and compromise component safety.

Solution: Project Path’s optimized path planning ensures uniform material deposition and reduces the risk of flaws.

Result: Enhanced durability and performance of critical compressed air system components, lowering failure risks and maintenance costs.

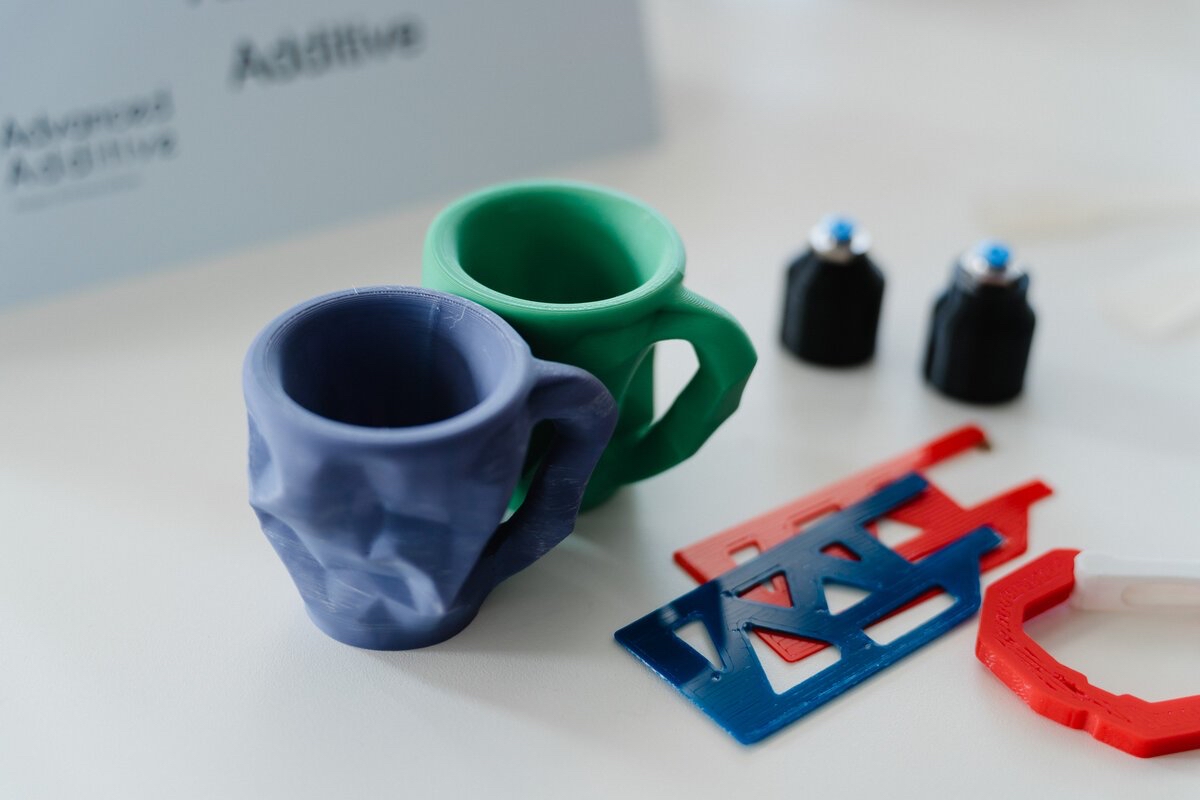

Plastic Components

Problem: Achieving consistent, high-quality plastic parts with minimal variation remains difficult.

Solution: Project Path delivers injection-molding-level precision while maintaining 3D printing’s design flexibility.

Result: Reliable manufacturing of strong, durable plastic parts suitable for prototypes and scalable production across industries.

Water-Tight Components

Problem: Ensuring water-tightness in printed parts is often challenging due to uneven material deposition.

Solution: Project Path guarantees consistent filling and bonding for leak-proof components.

Result: Superior sealing performance, reducing failures and expanding applications in fluid handling and sealing technologies.

Challenge us with your production problems! We surely can find a way to fix it!

Or let’s start a bigger Project exploring entirely new possibilities and become Partners for our long journey ahead. Let’s work together to turn your idea into a production-ready success story.

Benefits

Still unsure? Here are the three key benefits for your production and the future of additive manufacturing: Reliability, Flexibility and Openness for new companiess and vendors in the market:

Quality & Safety

Project Path sets a new standard for consistent and high-performance 3D printing in industrial environments. By optimizing the toolpath with unmatched precision, the software enables the production of mechanically robust, pressure-tight, and watertight components – reliably and repeatably. These properties are critical for applications in industries such as aerospace, automotive, and medical technology, where material performance and dimensional accuracy are non-negotiable. Even challenging materials like FDM-compatible sinter filaments or functional prototypes benefit from Project Path’s consistent path strategies. With our software, users can ensure stable production processes – from the first print to full-scale manufacturing.

Seamless Integration

Project Path was designed for real-world production needs. It integrates smoothly into existing digital manufacturing workflows as either a post-processor or plug-in – no workflow disruption, no new software environment to learn. Native interfaces, such as the integration into Zortrax Z-Suite, allow direct application of Project Path’s optimization within familiar systems. This ease of integration reduces the technical and organizational effort required to adopt new software and ensures quick onboarding across teams. Whether in R&D, prototyping, or full-scale production, Project Path enhances your process without requiring you to change it.

Universal Applicability

Thanks to its machine- and material-agnostic design, Project Path fits a wide range of production setups. Whether you’re using desktop printers or industrial systems, standard materials or engineering-grade filaments – the software can adapt. This universal compatibility not only maximizes your existing machine utilization but also ensures scalability without vendor lock-in. In addition, the platform is extendable to other additive processes such as SLS or future hybrid systems. For companies looking to standardize their process quality across technologies, Project Path provides a central solution that grows with your production needs.

Data Corner

The Data Corner gives a glimpse into our ongoing tests with Project Path. We share selected results, findings, and observations from different development stages – always based on real print data.

It’s our way of making progress visible.

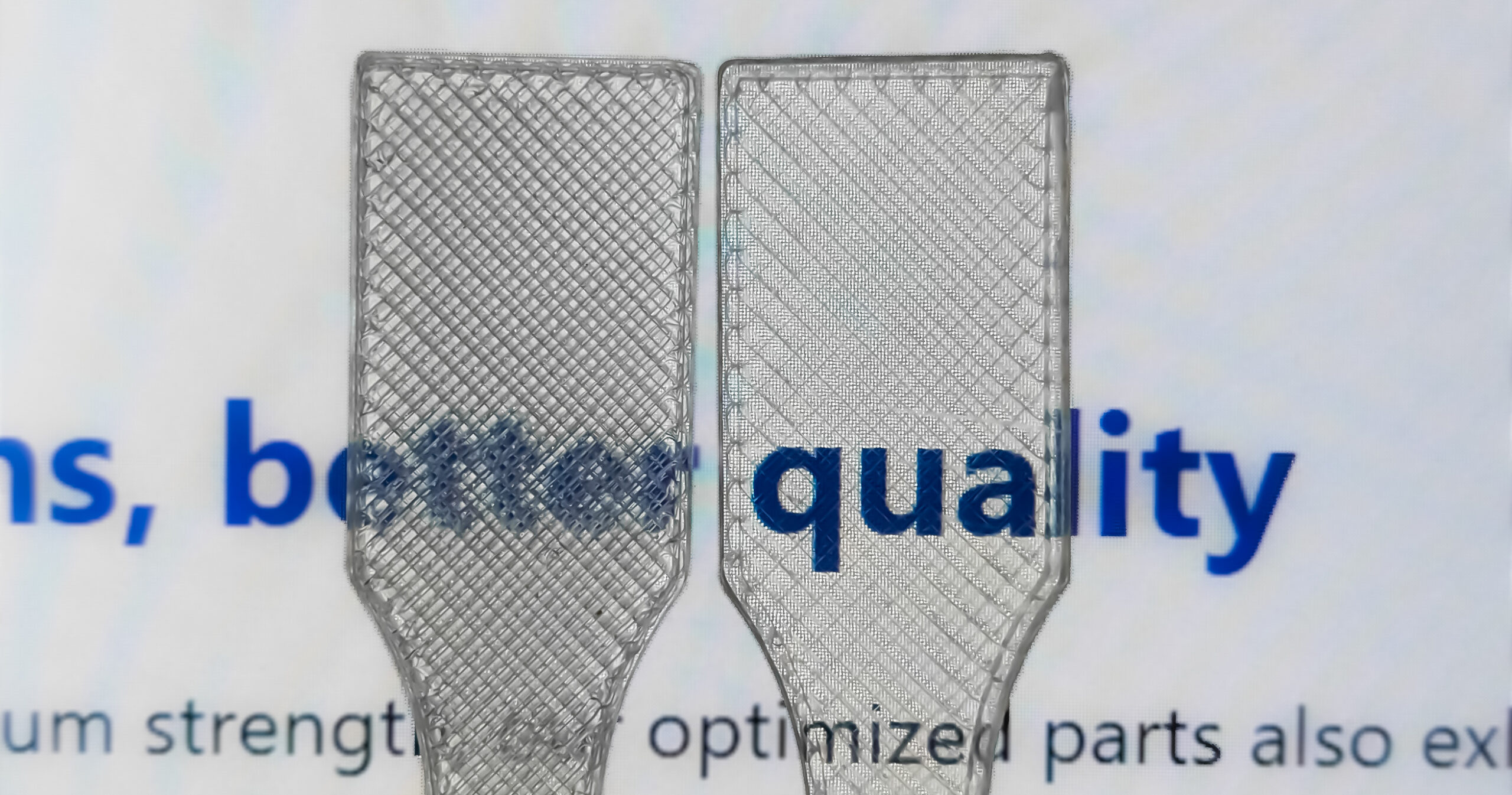

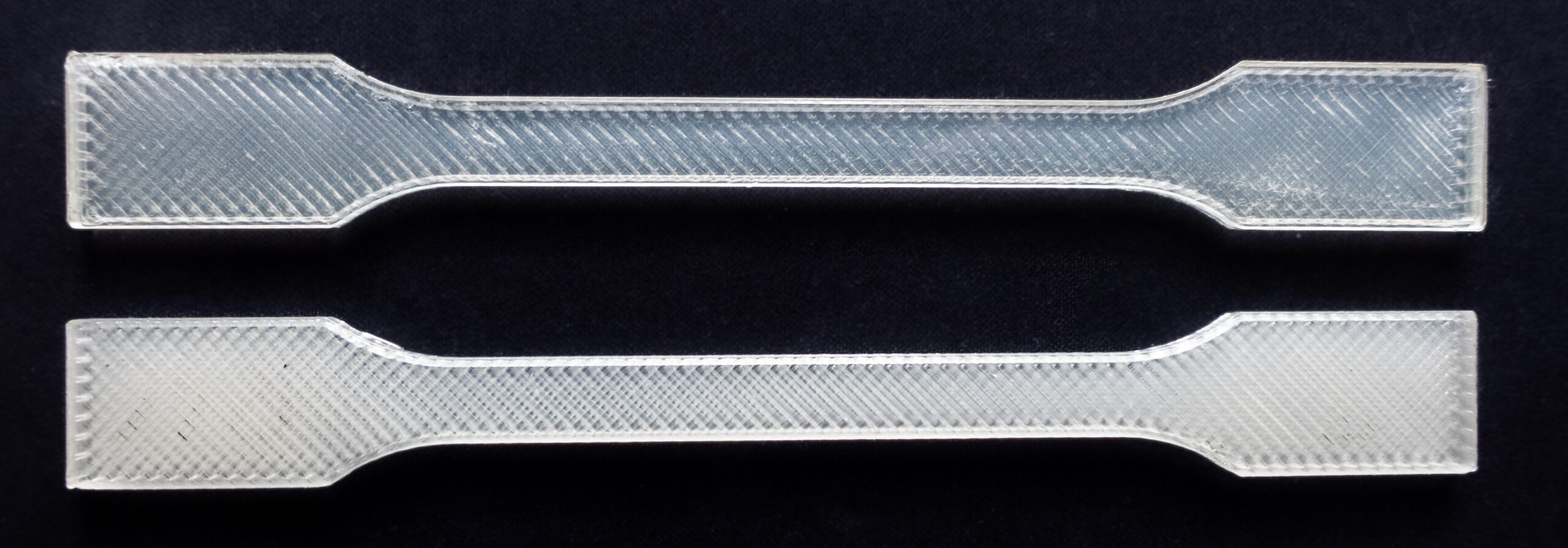

Tensile Tests

Test Series 1: 0,8mm Nozzle

Cura-produced parts displayed 67% more variation in standard deviation compared to injection-molded components. Project Path showed 2% less variation than injection-molded parts!

Key Metrics:

Injection Molding: 63.6 MPa

Cura: 58.67 MPa

Project Path: 63.16 MPa

Tensile Tests

Problem: Test Series 2: 0,4mm Nozzle

Cura-produced parts exhibited 3.3 times the standard deviation of injection molding. Project Path reduced this significantly, achieving 2 times the standard deviation of injection molding.

Key Metrics:

Injection-molding: 63.6 MPa

Cura: 54.26 MPa

Project Path: 58.03 MPa

Air & Gastightness

In this test (a bottle-like structure, Ø 30mm, wall thickness 6mm, effective height 30mm), we averaged a leakage rate of just 0.019 bar/h.

Our test part leaked roughly half as much as the Cura-generated part.

Leakage in the Cura part showed high sensitivity to pressure variations.

In contrast, our part demonstrated a nearly linear pressure drop.

What’s next?

Shaping the Next Generation of Industrial 3D Printing

At Advanced Additive, Project Path is only the beginning. We are continuously developing new features and tools to expand the potential of industrial 3D printing – with a strong focus on precision, scalability, and application diversity. Our upcoming releases are designed to address even more specific challenges in additive manufacturing.

- Brick Layer Strategy: A completely new approach to infill generation for better mechanical strength and print stability.

- Spiral Infill: Continuous, non-retracting inner paths for seamless flow and reduced start/stop marks – ideal for round and pressure-bearing parts.

- Screw extruder: Screw extruders have special mechanical properties but their application in industrial additive manufacturing is unchallenged. We can optimize to reduce the issues with these special properties to basically zero and make it a feasibly reliable industrial process.

- Advanced Slicer Integrations: Deeper integration into platforms such as Fusion 360 and Z-Suite for native, plug-and-play compatibility.

- Specialized Editions: Industry-specific solutions such as Project Path Medical and Project Path Space tailored to high-regulation sectors.

- AI-Based Path Optimization: A future-ready module to support even more complex geometries and requirements.

Let’s work together!

We’re actively looking for new pilot partners who are ready to push the boundaries of what’s possible.

Whether you’re working on complex geometries, high-performance applications, or materials with special requirements – we’d love to to team up and make your visions reality!

Your Production. Our Optimization. The Future of Industrial Manufacturing.